![]()

Fabrication & Enhancements

Customizing Your Component for Enhanced Performance

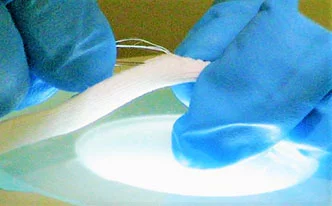

Engineering complex, fiber-based medical device fabric and components are just part of what we do here at ATEX Technologies. Once the component itself is created, there are many techniques we can employ to further enhance the functionality and performance of that product. Whether it is adding a specific location marker or weaving in metal fibers for enhanced visibility, ATEX possesses the capabilities required to provide our customers with a component that is completely customized and ready to flow into their assembly process. From cleaning to shaping to sub-assembly processing, ATEX can add value to your final device in a myriad of ways.

The right customization can enhance your component’s performance.

Our State-of-the-Art clean room is available for processing critical components.

ATEX has extensive material testing and characterization capabilities you can leverage.

Available Fabrication and Enhancement Capabilities:

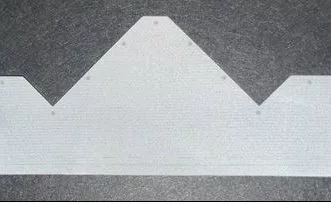

Precision Laser Cutting

surgical fabric

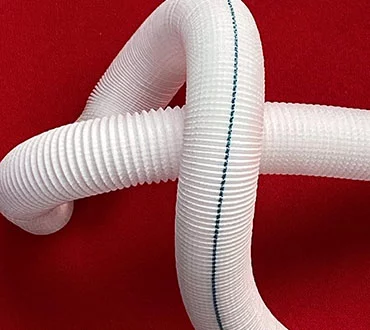

Ultrasonic Bonding

surgical fabric

Custom Coatings

surgical fabric

Heat Forming

surgical fabric

Sewing and Assembly

surgical fabric

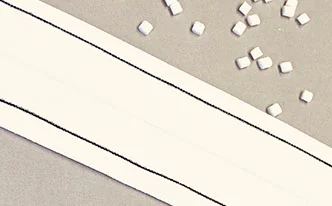

Fabric Marking and Dying

surgical fabric

Textile Cleaning Systems

surgical fabric

Clean Room Processing

surgical fabric

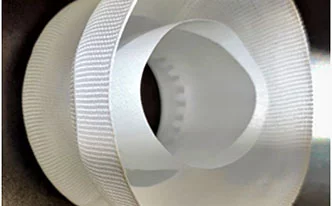

ATEX Technologies also has extensive internal yarn and fabric testing capabilities that are available to our customers for characterization of our medical device fabric and other textile-based materials such as three-dimensional pore size measurement using our highly sensitive vision system.

surgical fabric

![]()

Let's partner and innovate together

Have questions? Ready to get started? ATEX

is available to discuss the scope of your

component needs.