![]()

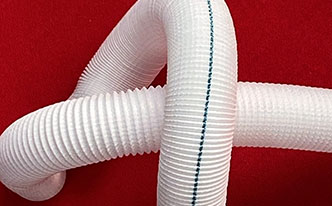

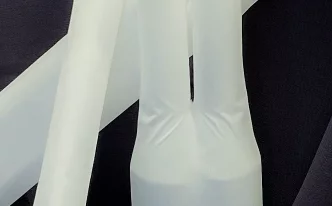

Component Shapes

High Performance, Custom Implantable Textile Shapes

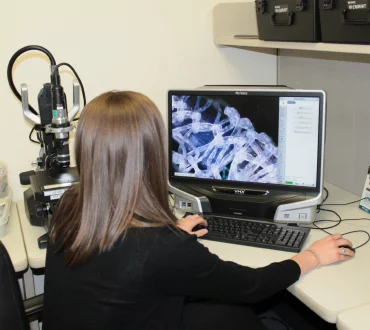

ATEX knows that the shape of an implantable textile component is intimately tied to its desired function within the body. Medical component shape, coupled with material choice and textile construction, all coordinate to enhance the overall performance of a product. By aligning the shape of the fiber based medical component with attributes such as conformability, material selection, surface features, permeability, strength, creep resistance and many other factors, the engineers at ATEX can create an implantable textile component solution that performs precisely and predictably in your medical device. From tubes and tapers to complex, three-dimensional biomedical structures, and everything in between, we thoroughly review customer design concepts, intended use and anatomical constraints throughout the development cycle to ensure that the implantable textile component performs exactly to the specification you provide.

Many of the most common medical component shapes we engineer are shown in the gallery below, along with links to more information about each. If your design has challenging constraints or is not an exact match of what is listed in the gallery, we suggest you contact one of our technical experts as these are only a small sampling of what we can do. Over the years, we have created multitudes of complex biomedical structures and components and are able to assist you in bringing your concept to reality. Talk to an ATEX technology expert today.

Unique Conformable Solutions:

Your specifications guide our process development.

Shape selection impacts component performance.

We engineer components for manufacturability right from the start.

Available shapes

![]()

Let's partner and innovate together

Have questions? Ready to get started? ATEX

is available to discuss the scope of your

component needs.